Introduction

Walmart has been at the forefront of retail modernization in China since 1996 when the first hypermarket and Sam’s Club were opened in Shenzhen. For more than 28 years, Walmart has contributed to the development of retail innovations in China. Ushering in a new era of omnichannel convenience, Walmart is dedicated to operating responsibly and helping create better lives for its associates and consumers in the communities where it operates. With more than 300 Walmart and Sam’s Club locations throughout more than 100 cities nationwide and multiple e-commerce platforms, they provide customers with an exceptional omnichannel experience and a wealth of opportunities to partners, suppliers, and associates.

I’ve tried multiple ways…But finally, we decided on a combined approach to blend traditional programming with low-code solutions.

Mr. Anthony Tsu

Senior Vice President, Integrated Supply Chain and Technology, Walmart China

Challenges

Walmart is dedicated to being the most reliable retailer for Chinese consumers. Aiming to enhance the consumer experience in multi-platforms with assurance of product quality and transactional efficiency, Walmart must follow the steps of realizing digital transformation and long-term cultivating of talent, community, and corporate culture. While this business giant never ends up satisfying customers with innovative solutions, such as its digital innovation in omnichannel retail, challenges hence arose.

Factors hindered Walmart’s transformation journey of digital innovation in omnichannel retail can be roughly summarized into three points:

Fast iteration of management systems

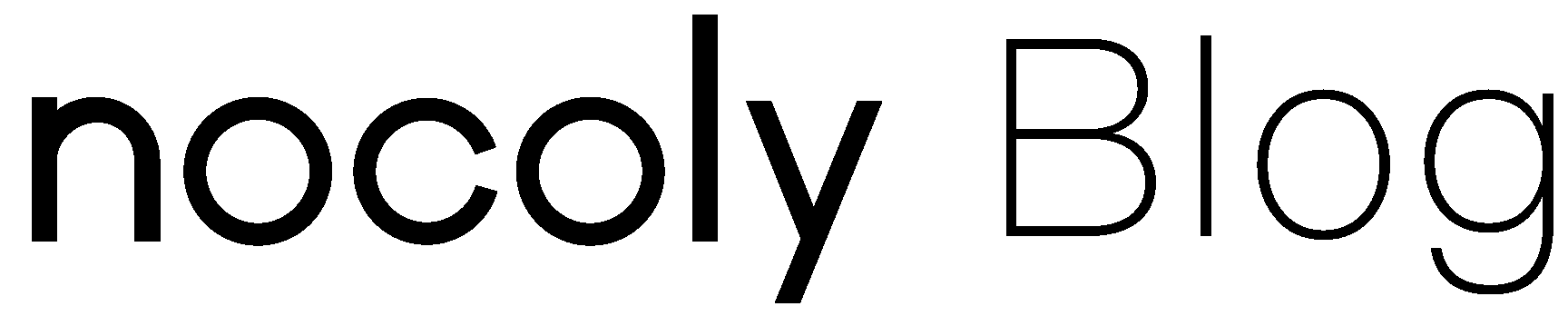

The rapid growth of e-commerce and changes in consumer behaviour led to an increasingly complex business landscape. System and management method built for one business scenario might not be a good fit for another that recently emerged. To ensure operation efficiency throughout various business scenarios, Walmart was also in eager need of a solution that enabled fast iteration of systems.

(Figure 1. Business Innovation of Sam’s Club)

Inefficient coordination

From e-commerce platform to supply chain management and from store operation to store fulfilment, more and more departments with their personnel were involved in daily operations, making it difficult to coordinate efforts across multiple channels, such as online orders, in-store pickups, and home deliveries. And a single choke point can affect the customer experience as a whole.

Full-range analysis of structured data

As external competition in retailing and e-commerce has become more and more fierce, Walmart needs to make use of a full range of data insights to help it win. However, the data collection process was hindered by un-integrated and fragmented data, which could lie in the chat box or email history. While these data could easily be ignored, they might lead to data quality problems.

Solutions

Through two representative projects of Walmart, we can showcase how HAP help clients in the retailing industry.

Project 1. Sam’s Cloud Warehouse Management

The online shopping business of Sam’s Club has grown rapidly in recent years, requiring faster construction of Sam’s Cloud Warehouse to meet members’ shopping needs. Sam’s Cloud Warehouse, a micro fulfilment centre (MFC), offers its members one-hour expedited delivery service to meet their demands for urgent good. The project team of Sam’s Cloud Warehouse are responsible for the standardization process, asset management, and expansion management of cloud warehouses. To better support Sam’s business development, a digital solution was in eager need to manage and coordinate the entire business process. This is where HAP comes into the picture.

In just one month, the project team utilised HAP to build a comprehensive cloud warehouse management system application, which later proved an asset when they saw how it improved efficiency and optimised processes. To cut down on processing time for routine and repetitive tasks, the team started by automating as many workflows as they could. The automotive workflow, together with automatic reminders, brought together seven departments and enhanced interdepartmental coordination. Additionally, the app dramatically eliminates obstacles posed by long-term spans and facilitates the implementation of real-time progress monitoring and retrospectives. The team also realized data centralized management by allowing the app gather the entire life cycle data of the cloud warehouse automatically and creating records of the whole process clear and traceable. Through trials and adjustments based on feedback from team members, the app is pretty mature now, and continues to bring convenience.

(Figure 2. Snapshots of Sam’s Cloud Warehouse Management Application)

Project 2. Quality Assurance Management

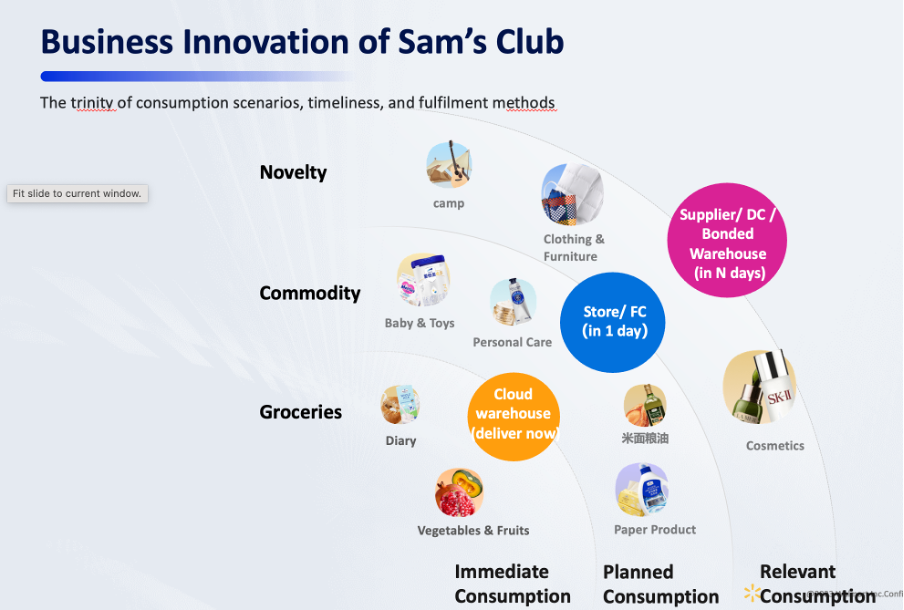

As the pioneer in retailing sector, Walmart places a high value on product quality, and a crucial components of that is quality assurance. In order to improve the quality of goods from suppliers in the long run, Walmart has its strict quality assurance framework which involves random inspection of goods and regular regulation of the operational personnel to reduce supply chain losses. Previously, the quality personnel in the distribution centre would check the goods on-site with the verification terms and put records. These data will be collected and saved in a shared document for later checking. If anomalies are found that need to be closed, they also need to be sent to the corresponding departments via email to complete the follow-up process. The old way of doing this requires much human effort and is inefficient when it comes to manually inputting paper reports and tracing abnormity by email. Walmart finally decided on HAP as the solution and built its comprehensive quality assurance system from 0.

(Figure 3. Snapshots of Sam’s Quality Assurance Management Application)

The landing of Quality Assurance app swap away the headache. The app first transferred all of the steps comprised in the quality assurance process to HAP online platform. From operation auditing to inspections recording, the app digitalised the entire process and maintained an extensive data trail that made it possible to trace back each step. Compared to the old method, HAP help prevent data loss and decrease manual labour. Second, thanks to HAP’s multi-platform nature feature, the team could simply make modifications to applications as part of system iterations. Once the changes are saved, the apps will update on all platforms immediately, enabling colleagues to do auditing tasks on mobile devices anywhere. Sufficient instructions, such as product calibration guidelines, were pre-uploaded into the app for users’ convenience. Following their completion of the required information, a few predefined functions will be activated to execute a number of tasks, including generating reports and calculating suggested sample ratios. Additionally, the app was used to manage cloud warehouse data centrally and included a aggregation of guidelines that are used to guide calibration and ensure instruments are fit for purpose. All of the cloud warehouse’s life cycle data was securely kept and used to create a real-time dashboard for monitor use.

Key achievement

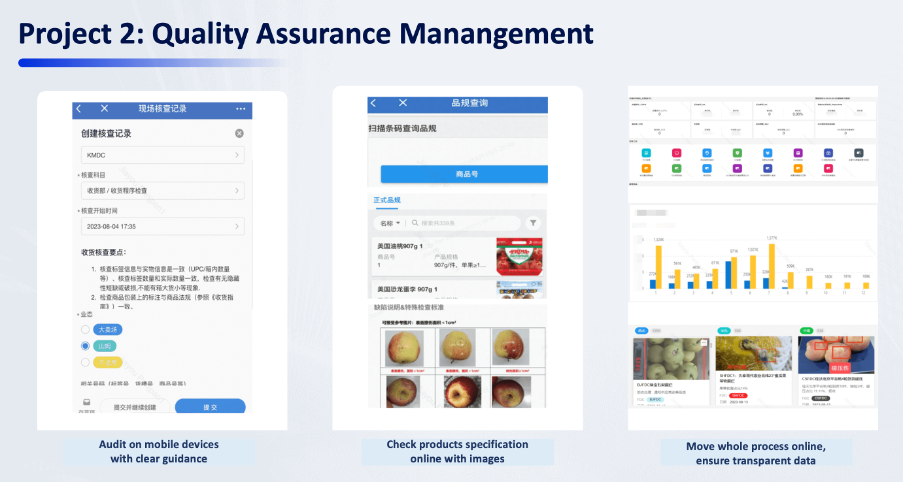

Using HAP for years, Walmart has mastered its full potential, and achieved a number of milestones along the way to its low-code revolution:

(Figure 4. Key Achievements of Low-code Transformation in Walmart by 2023.10)

Walmart employs HAP for daily business operation and internal management. The departments and systems that are engaged include, but are not limited to:

- Sam Cloud Warehouse Management

- Hypermarket Selection System

- IT Asset Management

- GIC Government Reporting System

- Industry-Research Collaboration Platform

- Attempted Case Management

- CRM-Large Order Customer Management

- License Compliance System

- Walmart Retail Learning Center Data Platform

- RTV-WMS

- Sam’s Delivery Rider System

- Fresh Food Management

- EOC Information Collection

- Supply Chain Management

- US Beef E2E Report Tracking