Introduction

Honda was jointly founded in 1998 by GAC Group and Honda Motor. Through its commitment to quality, innovation, and sustainability, Honda aims to strengthen its position as a leading automotive manufacturer in the region while delivering exceptional value to its customers and stakeholders.

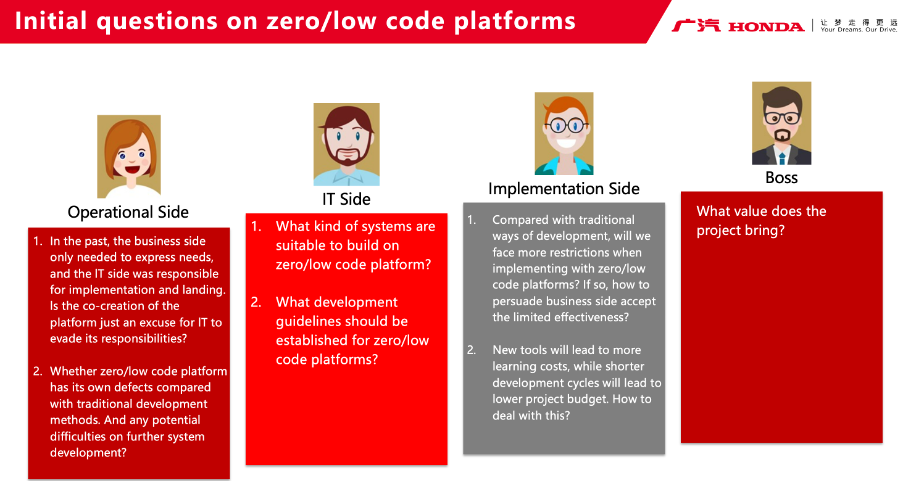

“Questions emerged from nearly all departments within the company when we proposed a low-code solution. We responded all beautifully.”

Mr. LI Liang

Head of Intelligence Manufacturing, Information Technology Department

Challenges

Currently, the vehicle manufacturing industry is facing an unprecedented revolution caused by emerging technology, including IoT, automatic driving, and AI. These new technologies are reshaping the industry (especially in vehicle functions and appearance) and accelerating business transformation. Nowadays, the automobile industry has grown into an essential pillar of the Chinese economy, realizing major achievements in the past decades. Automakers are facing more challenging situations than ever: more and more intense market competition, the need to answer consumers’ diverse needs agilely, and strict environmental policies have been carried out in recent days.

Honda divided its self-examined problems into three layers. First, the industry has a long product development cycle with considerable costs throughout every stage and involves cross-department and cross-geographical collaborations. Improving R&D efficiency and cutting costs has become an urgent problem for automobile corporations. Secondly, supply chain management in this industry is complicated since it involves many contractors, suppliers, and vehicle components. How to improve current supply chain management and cut stock to enhance the responsive speed of the supply chain also needs to be addressed. Besides, the process of vehicle production is thicket while high quality is required. Realizing smart manufacturing, improving production efficiency, and decreasing defect rates are other challenging problems that must be managed and solved. In short, what Honda is looking for is far more than just a single solution to one specific problem; it is a systematic one that can be implemented in all stages of the vehicle business throughout its transformation journey.

(Figure 1. Major concerns arise at the beginning)

Solutions

After exhaustive research and evaluation of no-code and low-code products in the market, Honda finally decided on HAP. We helped it set a comprehensive improvement plan to smooth its transformation, which comprised two core components: A digital talent cultivation plan and a Honda-All one platform.

Digital talent cultivation plan

Honda internally published its low-code platform, Borderless Co-Creation, based on HAP shortly after it announced its cooperation with us in April 2022. A series of training camps were provided to help front-line staff learn to use HAP and encourage them to exert creativity to build up applications to solve problems they are currently facing. This digital talent cultivation framework will ultimately realize democracy and self-governance in IT, of course, in the context of a secure and safe data environment.

Up to now, almost 100 training sessions have been held at Honda and its subsidiary companies to equip staff with sufficient digital skills. More than 800 technical experts were discovered from all departments within Honda during this learning process, while most of them are not from the IT department.

(Figure 2. Photos of training camps held at Honda)

With 2400+ applications being built and put into use, digital talents are still building core management systems to unlock HAP’s potential in enhancing business efficiency. Let’s see some examples:

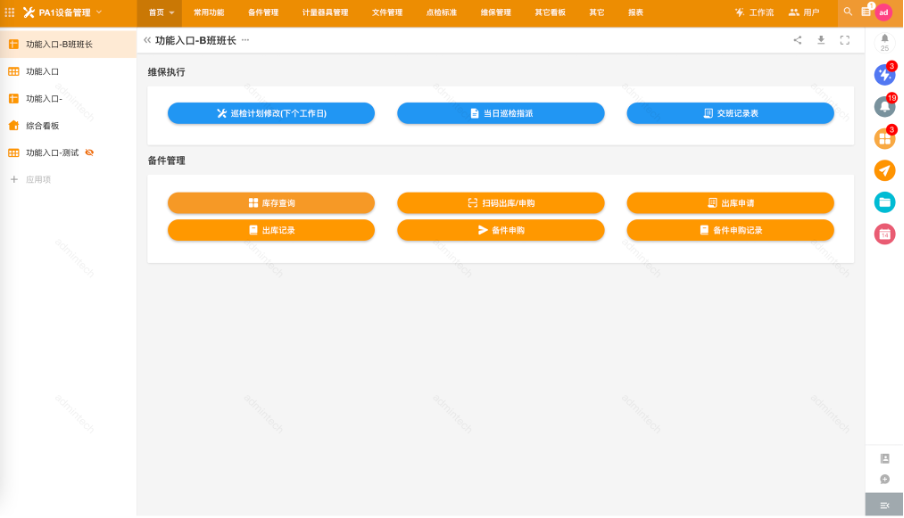

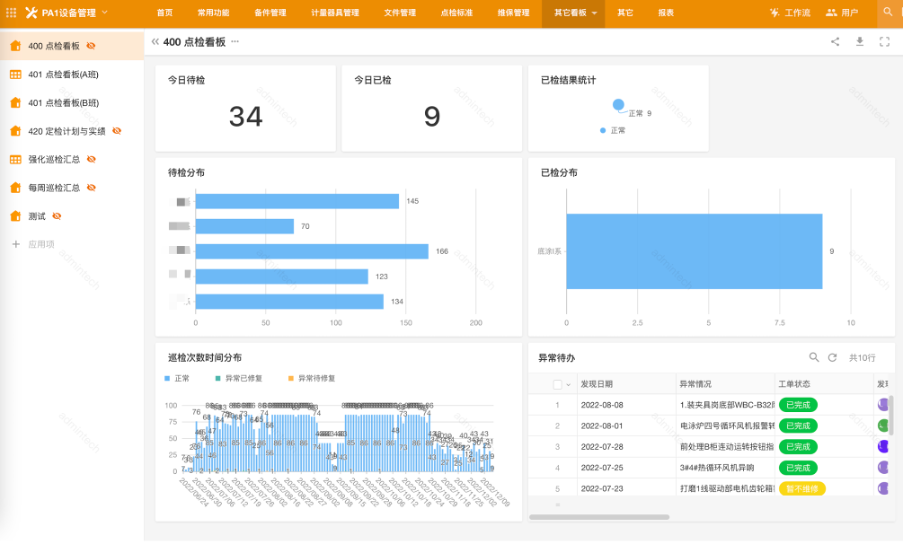

Equipment management system

One staff from a subsidiary company of Honda built up a mature equipment management system in three weeks, which includes core functions such as glitch repair and maintenance, equipment inspection and maintenance, spare parts management, and reminders for to-do items.

Before the landing of this application, all the enterprise’s equipment was managed separately using a PC-based system, Excel forms, and paperwork. With no unified management system, the management efficiency under this method gradually shows its disadvantage as the number of equipment and production load is increasing: low efficiency of equipment management business (e.g., equipment maintenance record statistics, tracking of legacy matters, accurate search for equipment information), and time lag in information (e.g., spare parts inventory information, requisition status information). As a result, an equipment management application was built to ease the pain.

(Snapshots of equipment management system built by a non-tech staff in 3 weeks)

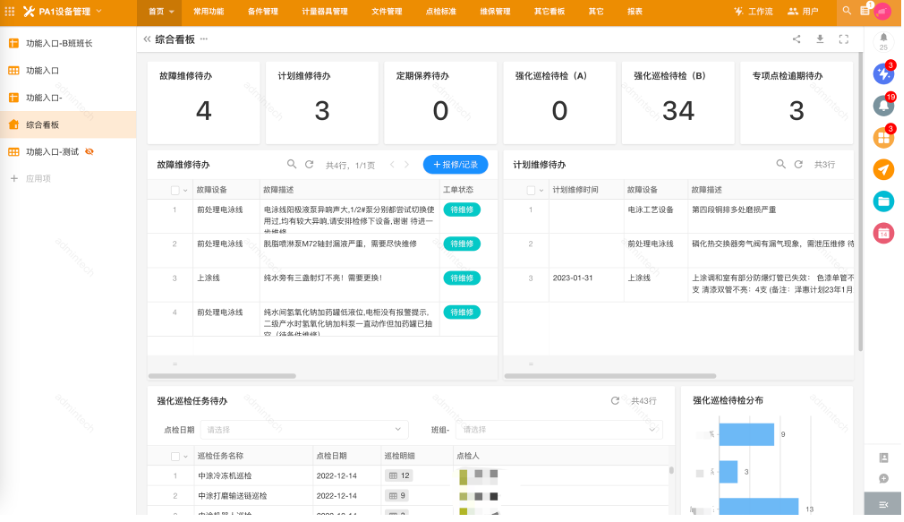

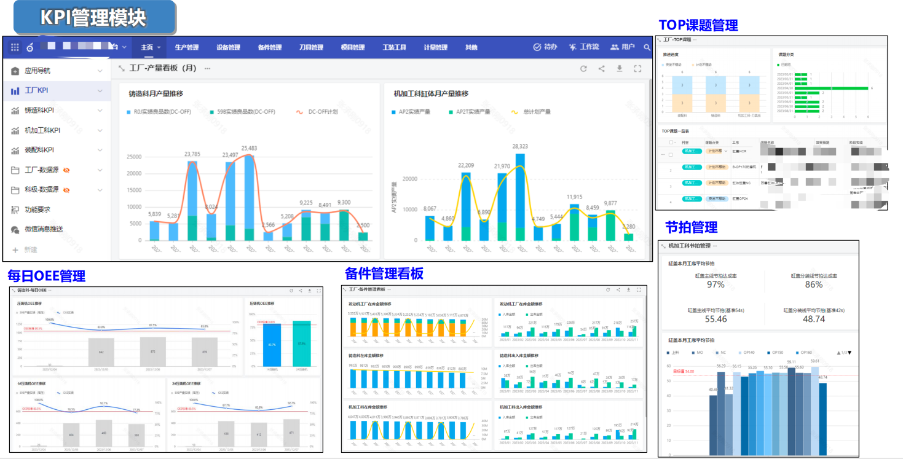

Smart production management system

After taking the HAP training courses, one staff member from the production department built an innovative production management system from scratch in just two weeks.

In the current manufacturing landscape, digital transformation is critical to improve productivity and reduce operating costs. Especially in the production area, which involves multiple business processes and data management, the traditional decentralized management approach can no longer meet the needs of modern factories. In order to optimize and integrate business processes, Honda factories decided to adopt Boundless Co-creation to consolidate the original 75 individual applications into one unified management platform. It took two weeks for one administration staff to build it from 0 to put it into use. The integrated platform contains eight core management modules at the beginning, with 59 sub-modules included, covering key business areas such as engine production, quality control, supply chain management, equipment maintenance, and so on. Other new functions added include automatic calculations of KPI indicators, which show real-time KPI calculation to ensure the accuracy and timeliness of sales data. Automatic real-time push management was also a highlight that helped monitor various business indicators in real time and automatically push key data to speed up the decision-making process. As a result, most management functions are now moving to online platforms with simplified management processes to reduce manual intervention.

(Snapshots of intelligent production management system built by a non-tech staff in 2 weeks)

Honda-All in one platform

Honda faces a series of challenges in its current enterprise management practice: the processes of unified management of employee records, optimization of organizational structure, and performance evaluation are lengthy and rely on manual multi-layer processing and confirmation. The Honda-All in one platform built by Honda is a one-dimensional platform based on HAP that effectively responds to these challenges.

Within three months, Honda, in collaboration with the business units, developed core systems, including organizational key management, evaluation management, room entry management, vehicle management, IT management, etc. The H-AIO platform is highly flexible and can be quickly adjusted according to the development and changes of business departments, thus continuously improving the efficiency of business processes and the overall effectiveness of management. This not only optimises internal management processes but also provides strong support for the company to maintain its leading position in the fiercely competitive market.

Systems independently developed by non-tech staff include:

- For personnel management and general affairs: Recruitment Management, Canteen Management, Systematic Management Department

- For production plants: Small Case Quotation Management, Mould Design and Drawing Management, Asset Waste Management

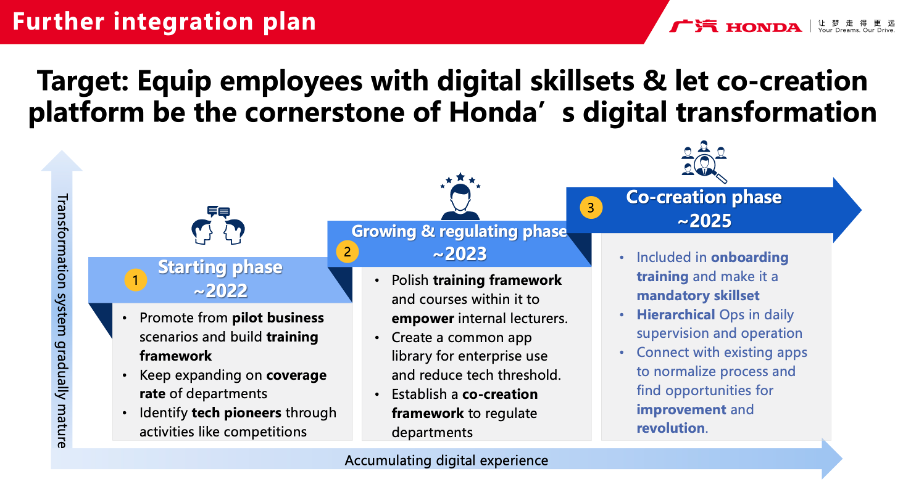

Future integration plan

While a number of milestones were achieved by Honda, the automobile giant will not stop exploring methodologies for further integration between its business and HAP. The image below briefly shows where Honda sees itself in the digital transformation plan.

(Future integration plan proposed by Honda)

Key achievement

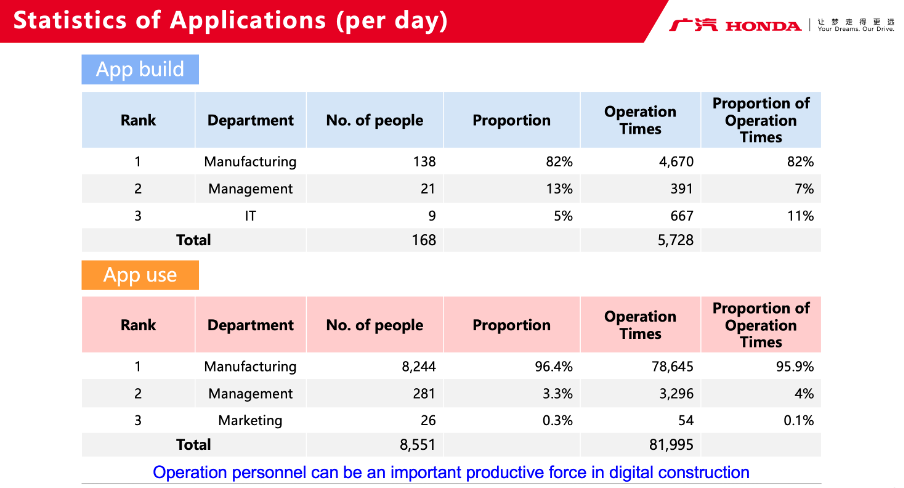

A list of achievements established by Honda from its initial adoption in 2022 to early 2023 is summarized below:

(Implementation results for Honda’s initial stage)

Up to now, Honda and its factories across mainland China have gotten used to the HAP-based Co-creation management platform in their daily operation. According to Honda’s newest update, they currently have:

- 2400+ apps launched

- 13,400+ workflows implemented to replace manual work

- 800+ technical experts discovered within the Honda

- 14,000+ department-wide and external vendor customers

The co-creation platform covers 100% of departments in daily business and is estimated to help Honda save CNY 10 million (80% of the previous development budget) per year.